Industry Selection

Identify Your Industry

Other Industries

Needs Selection

Identify Your Needs

Other Needs

You’re in good hands

Our Simple Guarantees

Complicated Guarantees don't encourage Peace of Mind or transparency...

That's why our guarantees are simple and easy to understand

service guarantee

Our service work is guaranteed for 60 days. If the repairs we make fail anytime withing 60 days, we provide a free loaner until the repair is corrected.

parts guarantee

Parts: Guaranteed for 12 months

Belts & Hoses: Guaranteed for 90 days

Rental guarantee

Delivered on time and ready to use or the first rental week is free.

Equipment guarantee

If your equipment doesn't perform as specified within 30 days of delivery, we'll buy the equipment back.

Looking For Something?

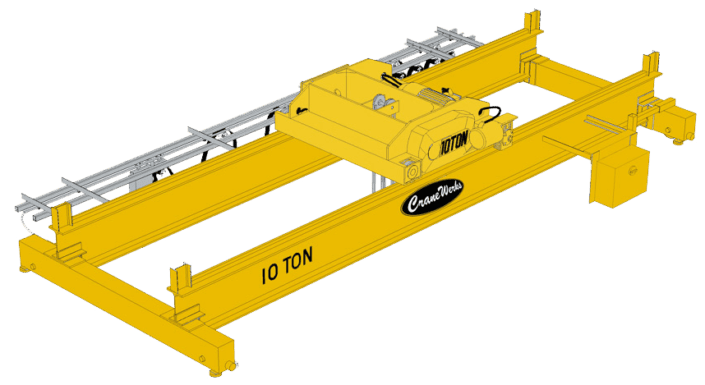

Find Equipment

Premier Fleet

Manage Your Fleet With Data

Average of 15% Savings in the First Year

Whether you want your data now or later, make sure you have it all. We set it up for you. No-touch Data Entry.

-

24/7 Emergency Services

Any time, any place...

We’re Your Best Choice

Why Black Equipment

Black Equipment is a service focused company accountable to our customers, employees, vendors and communities we serve. We invest in our people, technology and assets necessary to provide cost effective service, support, and equipment solutions to our customers. We work to earn the trust of our customers by acting with integrity and honesty. Our success is measured by the success and satisfaction of our customers, employees and vendors whom we serve.

FIND LOCATIONS

- Bowling Green, KY

- Evansville, IN

- Hopkinsville, KY

- Jackson, TN

- Jonesboro, AR

- Lexington, KY

- Louisville, KY

- Memphis, TN

- Mount Vernon. IL

- Paducah, KY