E-Commerce and Retail Fulfillment

By transforming the customer experience into one of extreme convenience, e-commerce has dramatically altered the retail landscape. Revolutionary advancements like faster shipping, increased personalization and omnichannel sales experiences give customers the power to shape the industry as they see fit, and businesses must adapt to stay relevant.

Investing in the right material handling solutions and equipment will help your business stay competitive as consumer expectations and geopolitical tensions continue to impact order fulfillment.

Emerging Trends in E-Commerce

Some of the top trends affecting retail and e-commerce operations include:

- Labor shortages: Hiring and retention issues increase dependence on temporary workers with limited training.

- Faster fulfillment: Tight delivery windows put immense pressure on distribution and fulfillment centers. Customers now expect one- to two-day shipping — or even faster.

- Returns management: Reverse logistics to handle returns are increasingly problematic. Returns range from 10% to 30% for retail and are over 20% for e-commerce.

- SKU proliferation: Increasing demands for personalization and customization mean businesses must handle a growing number of SKUs.

- Seasonal volatility: Peak seasons, like holidays, create inventory and labor surges that distribution centers must adapt to.

- Omnichannel fulfillment: Customers want a seamless purchasing experience, and omnichannel fulfillment techniques give companies more flexibility in managing orders and inventory.

- Digital transformation: Technologies like artificial intelligence (AI), blockchain and automation are proliferating across supply chains worldwide. These digital tools provide increased visibility for all stakeholders, as well as higher efficiency in order fulfillment.

- Cybersecurity: Increased digitization opens companies up to greater cyber risk, and cyberattacks can devastate the supply chain. Businesses should invest more resources into robust cybersecurity technologies and services to minimize losses.

- Sustainable shipping: Consumer demands and evolving industry standards drive advances in supply chain sustainability. Companies have devised initiatives to decarbonize logistics, shift to renewable energy and optimize routes.

Of these trends, new digital technologies will most likely disrupt the industry. Companies must invest in flexible, secure solutions that scale with their business to remain agile and competitive as the landscape evolves.

Material Handling Equipment Used in Warehousing

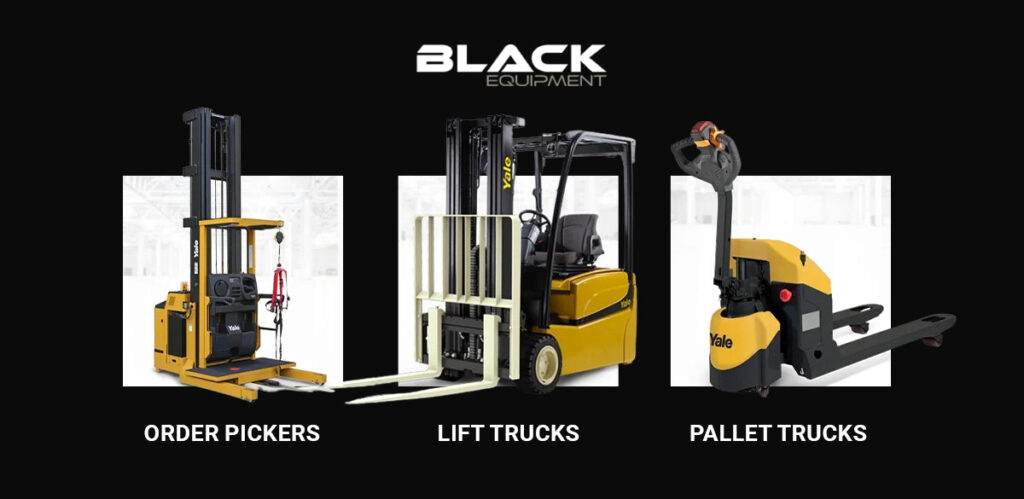

At Black Equipment, we’re passionate about helping warehouses reach their efficiency and productivity goals. Our experts can work with you to select the products that will accomplish these objectives. We carry a range of versatile e-commerce material handling equipment for sale or rent:

1. Order Pickers

Multilevel order pickers enable you to reserve the bottom levels of your warehouse for fast-moving SKUs and the top levels for slower-moving ones, potentially eliminating the need to add more pick slots.

Yale and Hyster order pickers include spacious, ergonomic compartments for maximum operator comfort and reduced fatigue. They integrate state-of-the-art technology features for more reliable, efficient order picking.

For instance, Hyster i3 Technology™ simplifies wiring and serviceability. It streamlines how operators use and service the vehicle by integrating software, functionality and diagnostic codes.

2. Lift Trucks

High-capacity e-commerce forklifts boost labor efficiency by reducing the trips operators must make to fulfill orders. Quick, precise positioning enables smoother picking and putaway.

Yale forklift trucks integrate an operator-focused design to boost productivity and efficiency in your warehouse. The mast and overhead guard-mounted display provide optimal visibility to help personnel work faster and more accurately. Additionally, the Yale three-wheel stand has one of the industry’s tightest turning radiuses, simplifying stacking even in restricted or congested work environments.

3. Pallet Trucks

Electric pallet jacks with advanced controls provide user-friendly solutions for optimizing delivery times and improving warehouse safety. A turning radius of under 5 feet enables seamless maneuverability in compact warehouse spaces. Lithium-ion technology allows for more efficient traveling, lifting and lowering — up to three times faster than a manual pallet jack.

At Black Equipment, we strive to provide our customers with the best in material handling equipment. We carry models from top brands like Yale, Hyster and COMBI-LIFT, giving you many options to fit your needs and budget.

Technology Solutions for Material Handling Applications

We can also help you enhance operations by incorporating innovative technologies, such as:

1. Telemetry

Wireless communication between machinery helps improve warehouse safety and efficiency. Telemetry provides information on equipment location, utilization, status, maintenance needs and operator performance.

2. Automated Guided Vehicles (AGVs)

Supplement your existing warehouse staff with automated vehicles designed to boost picking and transportation efficiency. Guided by software and sensors, AGVs can maneuver hazardous conditions and complex workspaces, like narrow warehouse aisles. They can perform repetitive tasks like transporting goods and materials throughout distribution centers, all without the assistance of a human driver.

Expedite the flow of heavy materials, reduce labor costs and enhance overall safety by incorporating AGVs into your workflow. You also don’t need to modify your existing infrastructure to use this technology. These vehicles accelerate material transportation by traveling along a predesigned circuit.

3. Dynamic Stability System (DSS)

Prevent accidents with built-in software that automatically limits equipment functionality in unsafe conditions. Integrated into Yale N and Hyster A Series forklifts, the DSS is an intelligent maintenance-free safety system that regularly assesses the forklift’s movement and operation.

The system accounts for variables like lift height, load weight and tilt angles and identifies potential imbalances. It then implements the necessary remedial measures like limiting the range of tilt or decreasing speed.

4. Operator Comfort

Ergonomic solutions such as assisted operation, cushioned floors and comfortable cabins help protect your operators from injury and maximize productivity. Plus, prioritizing operator comfort can help you retain more employees.

If you need assistance choosing a specific solution, speak with one of our experts. We’ll provide a comprehensive consultation addressing all your facility’s needs so you can truly optimize your processes.

Innovative Material Handling Solutions for E-Commerce

To address the challenges of e-commerce, companies must invest in holistic solutions that streamline their entire workflows rather than focusing on patch improvements here and there.

Some benefits of upgrading your material handling equipment include:

- Increase throughput with high-velocity order fulfillment and storage equipment.

- Reduce costs through advanced automation, preventive maintenance, improved uptime and right-sized fleets.

- Enhance safety and compliance with operator assist features and access controls.

- Gain visibility into utilization, workflows, training and impact events.

- Streamline deliveries by shaving valuable time off picking and distribution operations.

- Delight your customers by providing timely service and turnaround times.

Black Equipment can help you find and implement the material handling equipment and technology needed to streamline your workflows and maximize productivity.

Warehouse Design and Optimization

Effective warehouse design can benefit your facility by:

- Boosting productivity. Optimizing your space makes it easier for workers to navigate your warehouse by facilitating clearer, safer traffic flow between workstations and departments.

- Reducing costs. Every square inch of your facility adds to your total operating expenses, and warehouse space is at a premium. Streamlining your warehouse layout can help you offset leasing costs by increasing productivity and reducing your need for additional storage space.

- Improving safety. A well-designed warehouse gives machine operators sufficient space to flow from station to station without colliding with other workers.

Today, warehouse design includes incorporating emerging technologies into your facilities to further optimize your processes.

When you request a consultation from Black Equipment, our experts will assess your existing warehouse layout and material handling needs to identify or design the best solution. Whether you need to install loading dock door systems or right-size your fleet, we’ll advise you through each stage of your warehouse optimization.

Why Choose Black Equipment?

With comprehensive solutions and expertise, our team at Black Equipment has helped retail and e-commerce businesses solve material handling challenges for more than 50 years.

We’re more than a steady, reliable and fair partner. With 10 strategic locations throughout the Midwest, we have the resources and equipment to assist our customers in space planning, specifying fleet assets, transitioning to new workflows and planning new technology implementations.

Go beyond outdated technology and one-size-fits-all approaches. Contact Black Equipment today to learn how our consultative solutions can solve your unique needs.