Loading Dock Equipment and Doors

If your business is in the warehousing, manufacturing, logistics, agriculture segment or anything in between, the lifeblood of your daily productivity comes through your loading docks and doors. Our specialized knowledge and well-honed skills enable us to resolve any issue quickly and efficiently.

Complete Dock and Door Services & Repair

Black Equipment covers your loading dock needs from beginning to end, including ongoing preventative maintenance, repairs, and additional design and installations.

View our full scope of the services we provide our customers here.

Dock and Door Equipment Solutions by Category

For an area that can look stark and unimpressive, there are many components that go into a robust industrial dock area. Here are some of the key categories to be aware of when adding additional dock space or when considering the need for a preventative maintenance program.

Loading Dock Doors

Dock Levelers

Dock Lifts (Truck Scissor Dock)

Truck Restraints

Dock Communication Systems

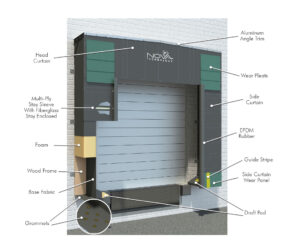

Dock Seals and Shelters

Dock Safety Accessories

- Doors: Loading dock doors come in many versions, such as sectional, rollup and swinging, to meet the needs of various material handling environments.

- Levelers: This piece of equipment serves as a bridge between the building at the door opening and the transport vehicle. It can be mounted at the dock faced or recessed into a pit.

- Shelters and seals: A shelter protects dock workers from the elements during loading and unloading. Seals close the gap between the door opening and the trailer.

- Truck Restraints: A vehicle restraint provides stability for the trailer and prevents it from rolling or bouncing during loading and unloading.

- Bumper pads and guardrails: These devices help prevent damage from vehicle collisions.

- Dock Lifts: Specialized equipment that raises loads from ground level to the truck bed level.

- Dock Communication Systems: Tools that provide clear, visible, and audible communication to facilitate safe and efficient operations.

- HVLS Fans: High-Volume Low-Speed fans, improve energy efficiency and reduce A/C Costs

Trust Us for Your Loading Dock Installation Needs

Properly maintained and serviced dock equipment and dock doors are essential for:

- Safety of employees, truck drivers, equipment, products, and raw materials.

- Meeting the demands of your customers with the efficient flow of critical products and materials in and out of your business.

- Energy efficiency with more consistently maintained interior temperatures with fast moving doors and door seals, de-stratified air by the use of high-volume low speed fans.

- Peace of mind that your dock area won’t be the bottleneck of your operations.

Your docks are critical traffic pathways that affect:

- Facility access & security

- Employee safety & comfort

- Safety of equipment, product, and raw materials

- Efficiency & productivity

- Regulatory compliance

- Energy conservation

- Convenience

- Aesthetics and brand consistency, and

- Your ability to deliver on your scheduling promises.

When easily avoidable mechanical issues cause your dock equipment or dock doors to malfunction, your productivity grinds to a halt. Poorly maintained doors and dock equipment put safety and productivity in jeopardy.

Yet due to their constant use and familiarity, loading dock and door equipment is often neglected, just waiting shut down your operations at the worst possible moment.

As a leader in material handling equipment sales, preventative maintenance, parts, and repairs, Black Equipment understands that our customers want a single source for all their fleet related issues. This not only includes your fleet equipment but also your racking, and the critical equipment and doors in your dock area.

Comprehensive Dock and Door Services: From Design to Construction

Dock Area Audits

- Condition

- Needs

- Safety, and

- Regulatory Compliance

Planning, Design, and Permitting

- Concrete Docks and Leveler Pits

- Levelers

- Electric for Power & Controls wiring of doors, equipment, and accessories

- Loading Dock Doors (function, styling, consistency/branding)

- Dock Seals & Shelters

- Dock Accessories

- Dock area OSHA Compliance

Construction Preparation

- Excavation

- Concrete Forming

- Utility Research and Placement

- Establishing Safety ‘No-Go’ Zones for Construction

Construction

- Electrical Power & Control Wiring Installation

- Concrete Installation & Finishing (including embedded anchors, steel edge protection, equipment mountings, power & controls wiring conduits, etc.)

- Dock Equipment, Electrical & Controls Wiring, Doors, Seals & Shelters, and Accessory Installation

Post-Construction

- Controls & Mechanical Testing & Training

- Customized Preventative Maintenance Plans

- Parts and Repairs of New or Existing Loading Dock Equipment, Doors, Controls, and Accessories

- 24hr. Emergency Service

- Trained crews equipped with the experience, parts, and tools to safely repair your dock doors and equipment.

Quality Loading Dock Equipment & Products

Black Equipment is proud of its wide variety of dock door & dock equipment solutions from our partnerships with industry-leading vendors like: Wayne Dalton Doors, NUCOR Company’s C.H.I.’s industrial overhead doors, Pioneer Dock Equipment, and NOVA Technology’s loading dock equipment safety and equipment solutions.

Loading Dock Area Accessories & Safety Equipment

- Traffic Lights to warn dock workers when to stay out of the trailer and tell truck drivers when it’s safe to move the vehicle.

- LED for Energy Savings

- Caution Signs to accompany loading dock traffic lights.

- Loading Dock Guide Lights for covered dock areas – so truck drivers can see darker dock areas.

- Super Bright LED for energy savings.

- Portable Dock Boards for Truck and Rail.

- Steel Yard Ramps

- Doorway Air Curtains

- Plastic Strip Doors for cleaner & more efficient work environment

- Security Gates

- No-Pest Ventilated Doors

Advantages of Black Equipment's Professional Installation, Preventative Maintenance, & Repair Services

EXPERTISE

We have the knowledge and experience to work with you to assess and design the most suitable docks and doors for your particular operational needs. Our crews are trained, tooled, and equipped with checklists to ensure all of your dock assets are regularly evaluated and maintained. Our crew’s experience and training help keep you up and running faster, safer, and more reliably while letting you focus on serving the demands of your customers.

PREVENTATIVE MAINTENANCE

Regularly scheduled checks and maintenance allow us to detect early signs of wear, tear, and minor damage that can quickly lead to unexpected downtime. By staying ahead of mechanical and other issues, we help extend the lifespan of your equipment while reducing larger impacts to your shipping and receiving productivity.

SPEEDY REPAIRS

When unexpected issues or damage occur, Black’s professional dock and door service can dispatch our parts-equipped service trucks to your facility for quick repairs that minimize your operational disruptions.

SAFETY COMPLIANCE

Our professional crews help ensure that installations, installed equipment, and maintenance practices comply with safety regulations, which helps reduce the risk of accidents and legal liabilities.

ENERGY SAVINGS

Dock seals and doors slowly degrade and lose their ability to help you maintain climate control within your facility. Preventative maintenance catches these breaches early to prevent unnecessary energy costs.

PRODUCTIVITY and EFFICIENCY

All of these services work together to keep your people safe and your operations productive. There are a surprisingly large number of dock assets to monitor and maintenance. Regular checks and maintenance are the only way to help prevent them from negatively impacting your business and potentially your reputation

Let Us Meet All Your Loading Dock and Door Needs

Contact Black Service today to speak with someone who can answer your questions about our Docks and Doors Services.