DC-64R™ For Refuse

Equipment type:

DC-64

Not all trucks are created equal. That’s why we designed the DC-64R, a severe-duty roll-off truck tough enough to handle the extreme demands and environment of construction. Every Autocar truck is custom-engineered and purpose-built for exactly what you need.

General

Manufacturer: Autocar

Model(s): DC-64R™ For Refuse

Dimensions

Engine

Operational

Features

- 325° Of Visibility From the Driver’s Seat

- 4,982 SQ/In of viewable glass area, 30% more than other conventional trucks. Wrap around windshield with tucked in A-pillars maximizes the forward visibility for safety.

- After Treatment Efficiency and Service Access

- Autocar delivers the highest level of body integration, partnering with body manufacturer’s for parallel engineering of body installation, pre-engineering chassis layout and pre-wiring components that enable seamless body integration.

- Autocar partners with exclusive partners to deliver a fully integrated roll off hoist, direct from the Autocar factory.

- Autocar set the Standard for best-in-class system durability, protection and serviceability. Water sealed connectors in easy to reach locations for fault finding and testing, breathable harness coverings for better protection to keep out water, dirt and chemicals, improved routing from the bottom frame flange and Hellerman Titan clamping system used to support the harness every 12”.

- Autocar works directly with body companies for parallel engineering of key body mount features to achieve the highest level of integration in the industry. This results in the things that really matter – more reliability and more uptime

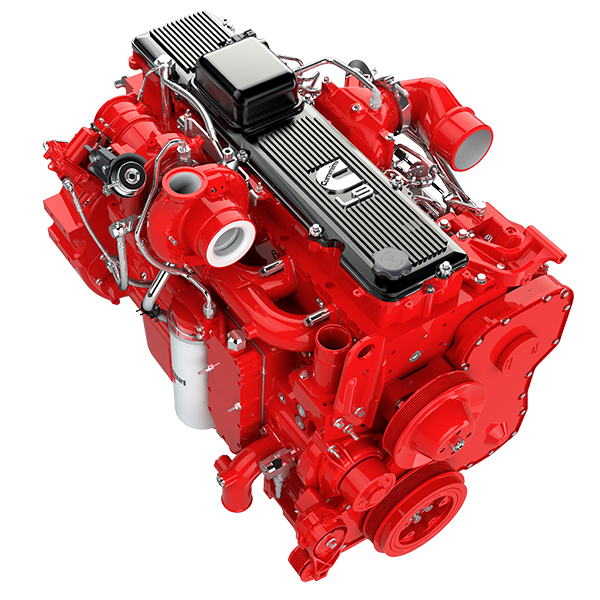

- Cummins Engines

- Cummins L9 and X12 engines – industry’s best performance, fuel economy, low Operating cost per mile, back by the best service and parts network.

- Cummins single module after treatment system requires less active regeneration and easy serviceability for exhaust after treatment system cover, with 8 fasteners, provides easy & quick unobstructed access, to access the diesel particulate filter for replacement in minutes.

- Driver Side

- Durability

- Electrical System

- Engine Bay

- Factory-installed Galfab hoist and tarper, huck bolted assembly, zero welding on the frame

- Front

- Hoist and tarper factory tested on every unit for quality assurance

- Interior

- Large cab space to provide the most comfortable, productive, and safest driver space offered. With ample foot, leg, hip, elbow and shoulder room and full adjustable seat and steering column.

- Large cab structure designed for all driver shapes and sizes and 325° visibility

- Maximum Cab Work Space

- Modern Driver Ergonomics

- More uptime delivers a lower cost of ownership for the life of the truck

- OEM assembled quality increases reliability and uptime with truck ready to work from the factory

- Passenger Side

- Power of One Integration

- Rear

- Reliability

- Safety

- Safety doesn’t happen by accident. This is why we’ve worked hard to bring our customers best-in-class driver visibility with a 325-degree visibility and a 112″ BBC with up to 50-degree wheel cut lowering steering effort and increasing job site safety.

- The Ultimate Power of One ™

- The all-welded steel cab construction provides maximum durability for your severe service applications. That is combined with a 160,000 PSI yield strength frame material 24% stronger than the industry-Standard and front tow pins that can handle 80,000 lbs of capacity.

- Through the Door

Options

- – 42% more low-end torque

- – Cut fuel costs by 40% versus diesel

- – No DEF or Regens

- – Reduce CO2 emissions

- – Saves thousands in reduced maintenance costs

- – Up to 600 lbs lighter means more payload

- Cng/Lng Options

- Cummins ISX12N

- Cummins L9

- Cummins X12

- Diesel Options

Industries

Downloads and Docs