Forklift Repair vs. Replacement: When to Fix or Upgrade your Equipment

Serving as both the backbone and muscle of your operation, forklifts allow you to perform tough warehousing, industrial, agricultural and ports & terminals jobs effectively and efficiently.

However, when these machines stall, so does your productivity. Your ability to service your customers grinds to a halt.

When this happens, you must answer the critical question: repair or replace? Your answer affects budget, productivity, safety, and more.

To make an informed decision, consider the forklift’s age, usage, maintenance history, costs, impact of downtime, overall performance, compliance with safety & regulatory standards, and more. Let’s take a closer look at how you can determine whether your forklift needs to be repaired or replaced.

What is Forklift Repair?

Forklift Repair is the process of diagnosing issues and fixing those issues. It’s what helps ensure you can continue to rely on your forklift equipment and keep it running safely and effectively.

Sometimes, you can anticipate the need for forklift repairs. Other times it’s a surprise.

Beyond the need for obvious fixes of mechanical, electrical, hydraulic and other issues, forklift repair can also involve preventive maintenance, scheduled inspections, and emergency repair.

Preventive maintenance aside, there are several indications that your forklift needs to be repaired.

9 Signs Your Forklift Needs Repaired

1. Unusual Noises or Vibrations

Forklifts should operate relatively smoothly and quietly.

- Grinding, squealing, or clunking noises may signal a problem with the engine, transmission or hydraulic pump.

- Excessive vibration may indicate a problem with the wheels or bearings or point to misaligned components.

2. Reduced Performance or Power

If your forklift isn’t pulling its weight, or if it’s operating sluggishly, you may need to have it repaired. Keep an eye out for these signs:

- Slow or weak lifting may signal hydraulic system issues or imminent pump failure.

- Difficulty accelerating or maintaining speed may point to engine or transmission problems.

- Jerky movements or delayed responses could stem from electrical or hydraulic issues.

3. Hydraulic System Issues

Because the hydraulic system is critical for lifting and maneuvering loads, be on the look out for:

- Leaking hydraulic fluid that puddles under the forklift or leaks on hoses or cylinders

- Erratic mast operation, including jerking, tilting unevenly, or failing to securely hold loads

- Slow lifting or lowering, which can indicate low hydraulic fluid, a failing pump, or worn seals.

4. Brake or Steering Issues

Issues with braking or steering demand immediate attention.

- Soft or unresponsive brakes can indicate issues with brake fluid, pads, mechanical or hydraulic brake components.

- Hard-to-turn wheels or erratic steering may signal problems with the steering mechanism or power steering system.

- Squeaking or grinding noises when braking suggest worn brake components.

5. Excessive Wear on Tires or Forks

Forklift wear and tears can manifest as:

- Uneven or bald tires that reduce traction, increase stopping distances, and risk load instability

- Bent, cracked, or worn forks that can fail under load

- Misaligned or damaged wheels that can affect stability and handling

6. Frequent Overheating

(NOTE: Warning lights & information screens can help make operators aware by pointing to temperature or other engine issues.)

Overheating can take on several forms:

- Engine overheating on internal combustion forklifts may result from low coolant levels, a failing radiator, or engine strain.

- Motor overheating on electric forklifts could indicate motor or battery issues.

7. Fluid Leaks

Any of the following fluid leaks are a sign of trouble:

- Engine or transmission oil leaks can lead to mechanical failure if not addressed.

- Coolant leaks resulting in low coolant levels can cause overheating and engine damage.

- Fuel leaks on diesel or propane forklifts are a fire hazard and require immediate repair.

8. Increased Exhaust or Emissions

For internal combustion forklifts, exhaust issues are a red flag. Take action if you notice any of the following signs:

- Excessive smoke that’s black or white could indicate fuel injection issues or worn piston rings.

- A strong odor of burning oil or fuel suggests leaks or incomplete combustion.

- Reduced fuel efficiency may point to engine or fuel system problems.

9. Electrical or Battery Problems

For battery-powered forklifts, you also need to be aware of potential electrical issues, such as:

- If the forklift runs out of power quickly or struggles to start, the battery or charging system may be faulty.

- Dim or flickering lights can indicate an issue with the electrical system or alternator.

- Unresponsive controls or dashboard warnings suggest electrical or wiring problems.

5 Common Forklift Repairs

Now that you know the signs that something is off with your forklift, let’s look at a few of the most common forklift repairs and how to address them.

Forklift dangers can present dangers in many forms. Please seek a qualified trained mechanic to conduct these and all other diagnostics, maintenance, and needed repairs.

The following are only suggestions based on common issues. They don’t represent the entire or even partial available solutions to potential repair issues.

Multi-variable issues can make diagnostics and repairs even more difficult.

Professional mechanics have been trained with respect to standard safety practices associated with these repairs. They also have the proper tools and diagnostic equipment. Unless you’re properly trained, don’t assume you can anticipate the many possible dangers associated with forklift repair. Safety should always be your foremost concern when doing repairs.

1. Hydraulic System Leaks

Cause: Worn seals, damaged hoses, or loose fittings in the system that powers the mast and lifting mechanism

Symptoms: Puddles of hydraulic fluid under the forklift, slow or jerky mast movement, or reduced lifting capacity

Repair:

- Disconnect the battery, lower the mast, and secure the forklift. Use lockout/tagout procedures to prevent accidental movement.

- Inspect hoses, cylinders, fittings, and the hydraulic pump to locate the leak.

- For worn seals, remove the affected cylinder and replace seals with OEM specific parts.

- Replace damaged hoses with high-pressure hoses that meet manufacturer specifications.

- Tighten and replace loose fittings as necessary.

- Refill the hydraulic fluid according to the operator’s manual and bleed the system to remove air bubbles.

- Test the system by operating the mast under load to ensure smooth lifting and no additional leaks.

Pro Tip: Moving forward, check fluid levels regularly and inspect hoses and seals during regularly scheduled maintenance.

2. Damaged Tires

Cause: Heavy loads, rough surfaces, sharp turns, and overloading

Symptoms: Cracks, flat spots, or uneven wear that affects stability or traction

Repair:

- Check for wear, cuts, chunking, or punctures in the tire.

- Assess whether the damage is minor and requires repair or more major and requires replacement.

- Park the forklift on a flat surface, lower the mast, and disconnect the battery. Lift the forklift using a jack and secure it with jack stands.

- For solid tires, use a tire press to remove the old tire from the rim. For pneumatic tires, deflate completely before removing.

- When installing new tires, use OEM or compatible tires. For solid tires, press the new tire onto the rim. For pneumatic tires, mount and inflate to the recommended pressure.

- Check that wheels are balanced and aligned.

- Operate the forklift on a flat surface to test traction and stability.

- It’s advised that you secure a trained mobile tire service technician to do this, or take your lift to a dealership with this service as removing and replacing forklift tires can be dangerous and requires training.

Pro Tip: Avoid overloading the forklift, maintain proper tire pressure, and inspect tires regularly to catch damage early.

3. Brake System Failures

Causes: Heavy use or neglecting regular inspections and maintenance tasks, leading to worn brake pads, low brake fluid, or contaminated fluid

Symptoms: Spongy or unresponsive brakes, squeaking or grinding noises when braking, and longer stopping distances

Repair:

- Secure the forklift by parking on a level surface, lowering the mast, and disconnecting the battery.

- Check brake pads, drums, and discs for wear.

- Inspect brake fluid levels and look for leaks in the brake lines and master cylinder.

- Replace worn brake pads or shoes with OEM parts.

- Replace or resurface scored drums or discs.

- For hydraulic brakes, flush and replace contaminated or low fluid with the correct type (per the operator’s manual).

- Remove air from hydraulic brake lines to restore pressure.

- Operate the forklift at low speed and test to ensure responsive braking.

Pro Tip: Check brake fluid monthly and replace pads and shoes as part of routine scheduled maintenance to prevent future issues.

4. Electrical Issues (Electric Forklifts)

Cause: Aging batteries, loose connections, or corrosion

Symptoms: The battery not holding a charge, dim or flickering lights, and unresponsive controls or dashboard warning lights

Repair:

- Disconnect the battery and wear PPE to avoid electric shock or acid exposure.

- Check the battery for corrosion, low electrolyte levels, or physical damage.

- Test the battery’s voltage and capacity with a multimeter or load tester.

- Remove corrosion with a wire brush and baking soda solution.

- Tighten loose connections.

- Top off electrolyte (if applicable). For lead-acid batteries, add distilled water to maintain proper levels, per manufacturer guidelines.

- If the battery fails testing, replace it with a compatible model.

- Inspect wiring, fuses, and controllers. Replace damaged components with OEM parts.

- Charge the battery fully and test the forklift’s operation, including lights, controls, and lifting.

- Some dealerships offer battery conditioning services for again lead-acid batteries. This often restores significant lost capacity which provides longer run times and battery life.

Pro Tip: Follow a battery maintenance schedule (e.g., regular watering, equalizing charges) and avoid overcharging.

5. Mast or Chain Wear

Causes: Mast and lift chains enduring heavy stress from lifting loads becoming worn, misaligned, or elongated

Symptoms: Jerky or uneven mast movement, inability to lift loads to full height, or visible wear, rust, or lengthening of lift chains

Repair:

- Lower the mast, disconnect the battery, and secure the forklift to prevent movement.

- Check chains for elongation (typically beyond 2-3% of their original length), rust, or damaged links.

- Carefully inspect mast rollers, bearings, and guides for wear or misalignment.

- Apply manufacturer-recommended lubricant to chains and mast components.

- Replace elongated or damaged chains with OEM-specified chains and worn mast rollers or bearings to ensure smooth operation.

- Ensure chains are properly tensioned per manufacturer guidelines to avoid slack or strain.

- Test the mast under load to verify smooth lifting and lowering.

- Pro Tip: Lubricate chains and mast regularly, avoid overloading, and inspect for wear during routine maintenance.

Repair Pitfalls to Avoid

While it’s important to know the kind of repairs forklifts typically require, you should also take note of potential pitfalls you will need to avoid when repairing them.

Keep in mind that making any of these mistakes can lead to higher repair costs over time, higher safety risks, increased downtime, and reduced overall lifespan of your forklifts.

| MISTAKE | HOW TO AVOID |

| Ignoring Manufacturer Guidelines | Always read the operator’s manual and follow recommended procedures. |

| Assuming Root Cause of Repair Without Evidence | Enlist a trained and qualified technician to perform diagnostic testing. |

| Using Cheap or Low-Quality Parts | Source OEM or high-quality aftermarket parts from reputable suppliers. |

| Allowing Untrained Personnel to Make Repairs | Hire certified forklift technicians with experience in your forklift’s make and model. |

| Overlooking Safety Precautions | Follow ALL industry repair safety recommendations, such as but not limited to: Always disconnect the battery, lower the mast, and secure the forklift before repairs. Use proper PPE and follow lockout/tagout procedures. |

| Failing to Test After Repairs | After repairs, test the forklift under normal operating conditions to make sure the issue is fixed. |

| Neglecting Related Systems | During repairs, inspect related systems for wear or damage. |

| Failing to Document Repairs | Maintain a log of all repairs, including dates, parts replaced, costs, and technician notes. |

| Ignoring Operator Feedback | Encourage operators to report issues immediately and train them to recognize warning signs. |

8 Benefits of Preventive Forklift Repair

It’s important to remember that forklift repair can also include preventive maintenance, sometimes referred to as ‘preventative maintenance’ or ‘planned maintenance’.

While it may seem like a hassle to temporarily take your forklift out of commission for preventive maintenance, doing so will help you avoid downtime, safety incidents, and even costlier repairs down the line.

Here’s a closer look at the benefits of planned maintenance.

1. Reduced Downtime

Regular planned inspections and servicing based on equipment usage levels allow technicians to catch potential issues before they result in unexpected breakdowns.

What’s more, planned maintenance allows you to spot potential problems and procure another rental truck ahead of time so that you can minimize or even eliminate your overall downtime.

2. Lower Cost of Repair

Planned maintenance that addresses small problems like worn brake pads or low fluid levels typically costs less to fix than damage that’s built up over time within major components like the engine, transmission, brake, or hydraulics.

3. Extended Lifespan

Routine checks and maintenance tasks like lubricating chains, checking tire wear, and cleaning filters help prevent excessive wear on your forklift, extending its usable life.

4. Increased Safety

Preventive maintenance helps ensure crucial systems like the forklift’s brakes, steering, and hydraulics are in good working order, helping mitigate operator risk.

Plus, when your operators know you’ve developed systems and processes to keep them safe and allow them to do their work seamlessly, they are more likely to stay with your company.

5. Enhanced Efficiency

Forklifts in working order typically result in faster and more efficient operations, not to mention less downtime.

6. Regulatory Compliance

Regular and preventive maintenance helps ensure your forklift complies with industry standards and regulations, helping you avoid fines, penalties, and liabilities.

7. High Resale Value

A well-maintained forklift retains its value longer, meaning it will be less of a hassle to sell or trade in when you decide to do so.

8. Reduced Environmental Impact

Forklifts that operate inefficiently result in higher fuel consumption and emissions, increasing your carbon footprint and impacting your sustainability goals.

Forklift Repair & Service

If you ever experience any doubt as to what needs repaired on your forklift or how to do it, Black Equipment is here to help.

Black Equipment helps you cover all the bases, including:

- 24-hour emergency service for all customers

- Planned maintenance programs based on your equipment, environment, and workload

- On-site repairs

- In-house maintenance for larger/complex issues

- Guaranteed maintenance programs

What is Forklift Replacement?

In some cases, your forklift may be beyond repair, and it’s time for an upgrade. That’s where forklift replacement comes into play.

Forklift replacement is the process of swapping out aging, inefficient, or underperforming machines with new models to increase efficiency, safety, and cost savings.

Here are signs it’s time to purchase or lease a new or used forklift.

6 Signs Your Forklift Needs Replaced

1. Old Age or High Operating Hours

If your forklift is over 10 years old or has exceeded 15,000 hours, it may be time to replace it.

Pro Tip: Note that as your forklift increases in age, it may also be harder to find parts, and its resale value may decrease.

2. High Repair and Maintenance Costs

If repair costs exceed 50-60% of the forklift’s current value (for example, a $5,000 repair for a forklift worth $8,000), it’s time to say good-bye to your current forklift. Remember that recurring issues like hydraulic or engine failures not only drain your budget, but they also disrupt your operations more often, meaning you have to contend with more downtime.

Similarly, note that rising fuel costs due to fuel inefficiency and slower cycle times also put a dent in your bottom line.

3. Inadequate Performance for Operational Needs

If your forklift consistently struggles with current load capacities or lifting heights, operates sluggishly, or is unable to maneuver smoothly, it’s clear it can’t keep up with your current operation.

Similarly, if operators report discomfort, fatigue, or difficulty using the forklift, productivity is declining due to slow or unreliable equipment, or frequent operator errors are linked to outdated controls or poor ergonomics, it may also be time to make the switch.

In other cases, your forklift may be operating fine, but you may notice that your operation has evolved and now requires higher demands than your current forklift can keep up with.

4. Outdated Technology + Low Compatibility

Make sure you’re paying attention to operator complaints about your current forklifts being uncomfortable or difficult to operate.

Also, if your forklift is not compatible with current attachments or warehouse systems and lacks modern features like ergonomic controls, telematics, or automated safety systems, it may be time for a switch.

5. Safety and Compliance Issues

If your forklift experiences recurring safety problems like faulty brakes, steering, or mast instability—even after repairs—it’s time for replacement, especially if the machine has fallen out of compliance with current OSHA or industry regulations.

Pro Tip: Updated forklifts contain modern safety features, such as backup alarms, lights, cameras, OSHA pre-flight checklists, stability controls, and much more.

6. Environmental and Sustainability Goals

If your forklift is not fuel efficient or if your area must abide by environmental regulations, you may want to consider upgrading to electric forklifts or a low-emission option.

What to Consider When Upgrading a Forklift

If your operation has experienced the above situations, and you’ve decided that now’s the time to replace your forklift with a newer model, there are a few things you must consider.

1. Intended Usage

- For what applications do you plan to use the machine?

- Do you plan to use it indoors or outdoors?

- How often will you be using the machine?

2. Attachment Compatibility

- Can the replacement lift truck work with your current or needed attachments?

3. Fuel Type

- Will you be purchasing a propane-, diesel-, or battery-powered machine?

- Does your locality enforce emission requirements?

- Will your forklift align with the environmental regulations during your period of ownership?

4. Load Capacity

- How much can the forklift carry?

- What are your operation’s requirements?

- This includes consolidation of lift heights & tilt requirements?

- You may also need to consider mast height constraints through tight areas and doorways.

5. Ergonomics + Comfort

- Will the new technology be easy to onboard?

- Is the forklift easy to use?

- Does it include features geared toward operator comfort?

6. Ease of Service

- Is the forklift easy to maintain?

- Are there systems in place to assist with maintenance alerts and schedules?

7. Ongoing Support

- Is the manufacturer reputable and reliable?

- Is the dealer available to provide ongoing support and answer any questions you have?

- Can the dealership provide operator and/or ‘train-the-trainer’ training?

8. Safety Compliance

- Does the forklift meet and exceed safety standards?

- What added safety features are included?

Cost of Forklift Repair Vs. Replacement

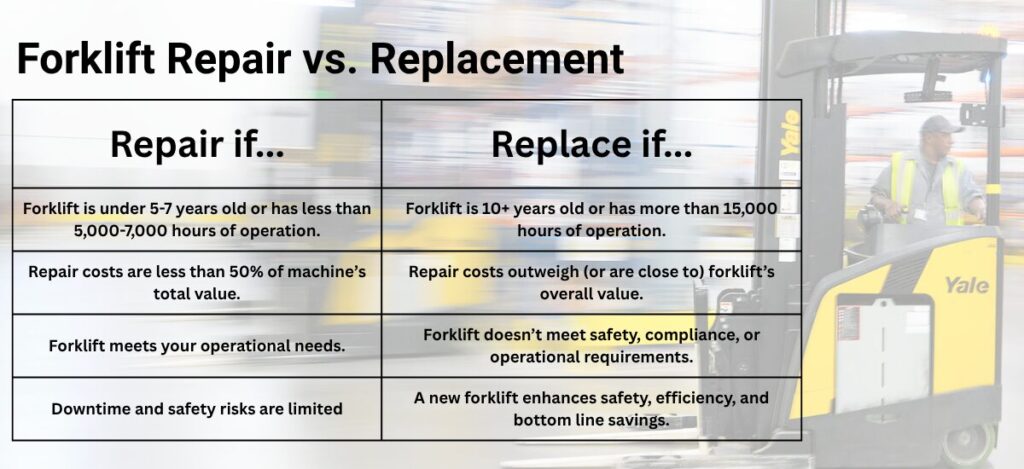

While forklift repair is often the most economical response to forklift issues, it’s crucial that you compare repair, replacement, and overall cost of ownership costs.

A common rule of thumb is that if repair costs exceed 50-60% of the forklift’s current market value, replacement is often the better option.

In summary, here’s quick guide to help you decide.

Final Thoughts: Repair Now, Save Later

If you have questions about how to repair your forklift, how to implement a maintenance schedule, or what to look for in a replacement forklift, Black Equipment is here to help.

And remember that time and money geared toward maintaining and repairing equipment now will lighten your load when it comes to headaches and costs down the road.

The seasoned experts at Black Equipment can help you decide if it’s economically better to continuing maintenance and repairs on your current forklift, or upgrade to a better USED or NEW forklift.

OR

Click for your local branch