Choosing Between ICE and Electric Forklifts: A Comprehensive Guide

The type of motive power a forklift uses can have a significant impact on an operation’s productivity and efficiency, so it’s critical to choose the model that best fits the application. However, determining which drive system you should choose can be challenging without specialized insight or experience.

Having as much information as possible and consulting with experienced professionals are key. This guide provides the important background needed to get started.

1. ICE Forklifts

ICE forklifts contain internal combustion engines (ICEs) similar to those of other fuel-powered vehicles. These engines burn different fuel types to generate mechanical power, such as:

- Liquid petroleum gas (LPG)

- Diesel

- Compressed natural gas (CNG)

- Gasoline

As the established mode of motive power across various industries and applications, the internal combustion engine provides high reliability and long hours of operation.

Pros of ICE Forklifts

Advantages of ICE-powered forklifts include:

- Consistent performance: ICE forklifts have been the industry standard for decades, making them a safe and dependable option for high-intensity applications.

- High power: The engine’s design enables ICE forklifts to produce bursts of intense power, which can enhance efficiency and maximize uptime even in challenging use cases.

- Versatility: The dependability and power capabilities of an ICE forklift make them suitable for many different use cases in industrial and outdoor operations.

- Quick and easy refueling: Operators can quickly refuel ICE forklifts with minimal disruptions to their operations.

- Lower initial investment: Generally, ICE forklifts are less costly to purchase than electric models due to their established presence within the industry.

- Continuous operation: Because ICE forklifts don’t depend on electricity to run, crews can continue working through outages that would cause problems for electric-powered forklifts.

Cons of ICE Forklifts

Some important drawbacks to consider include:

- Higher maintenance requirements: The complex design of mechanical engines requires more frequent preventive maintenance intervals and, often, more costly repairs.

- Lower torque: An ICE forklift takes significantly more time to produce high levels of torque, which reduces the operator’s capacity to accelerate when needed.

- Hazardous emissions: Internal combustion engines produce toxic exhaust, which can harm indoor workers unless properly vented. Failure to manage these emissions can also impact a company’s ability to comply with new and evolving environmental regulations, potentially leading to high fines.

- Limited flexibility: Due to the toxic exhaust they produce, ICE forklifts are only safe for use in outdoor spaces or well-ventilated indoor facilities.

- Unpredictable cost of operation: Cost fluctuations for fuel and storage space can make creating an accurate budget more challenging, which can impact other important financial considerations.

Applications for ICE Forklifts

ICE forklifts are highly versatile and able to provide effective power to various applications across different industries. Some examples of applications that can benefit from an ICE forklift include:

- Manufacturing: ICE forklifts provide sufficient power and speed to efficiently transport pallets of supplies and raw materials between different areas of a manufacturing facility to help ensure a continuous workflow.

- Warehousing and distribution: An ICE forklift can quickly pick and transport orders so online retailers and distributors can deliver the fast service customers have come to expect. ICE forklifts can also provide extra efficiency in loading and unloading delivery trucks, helping ensure the constant movement of goods throughout the value chain.

- Outdoor materials storage: An ICE forklift enables operators to efficiently stack and sort containers of loose materials for smooth, streamlined workflows.

- Waste disposal: Waste management companies and any facility that must dispose of unhygienic waste can use ICE forklifts to quickly remove the waste from their worksites.

- Construction: Construction crews can use ICE forklifts to unload deliveries and move those building materials to specific areas on the jobsite to save valuable time and effort.

2. Electric Forklifts

Electric forklifts do not rely on fuel and combustion for motive power. Instead, they store and use electrical energy in one of three types of batteries:

- Lithium-ion: These low-maintenance batteries provide flexible, dependable power in modular designs so fleet managers can scale for additional capacity.

- Thin plate pure lead (TPPL): TPPL batteries last long and charge quickly, so they’re effective for multi-shift operations.

- Lead acid: An established battery type, lead-acid batteries provide a reliable and cost-effective option for general forklift applications. However, it’s important to note these batteries are inefficient and short-lived compared to newer technologies — and usually need to be swapped out to keep the forklift productive.

The most appropriate battery for your application will depend on several factors, including typical working hours, number of shifts, available charging time between shifts and breaks, space limitations and more. Consult with an experienced professional who can help you decide which model you should purchase, as they can provide insight into important differences between options that may be required for your operational demands.

Pros of Electric Forklifts

Electric forklifts are good for many applications due to these features:

- Low maintenance requirements: Fewer moving internal parts reduces wear-generating friction, which reduces maintenance frequency and costs.

- Reduced operating costs: Electric batteries reduce the amount of consumables you need to run typical operations, which keeps costs low.

- Immediate torque: Unlike internal combustion engines, electric motors provide high torque on demand.

- Smooth and precise operation: Electric forklifts provide more torque than those with ICEs and offer smoother acceleration and more precise control. This makes it easier to maneuver through tight and crowded spaces.

- Low noise: Electric engines produce significantly less noise than conventional ICE models and are suitable for enclosed facilities where loud machinery can be hazardous. Their quiet operation also makes them better suited to urban or natural areas where noise pollution can impact the surrounding environment.

- Longevity: Electric forklifts generally have longer lifespans than their internal combustion counterparts, which could save thousands in new equipment costs.

- Newer technology: Early adopters can future-proof their operations because electric forklifts provide access to the latest forklift technologies that can help enhance workplace safety, simplify preventive maintenance and streamline fleet management.

Cons of Electric Forklifts

Some drawbacks of electric forklifts can include:

- High upfront costs: While electric equipment typically requires a higher upfront investment than traditional ICE-powered models, they can be more cost-effective over time. Financing options can also make them more accessible for companies with limited resources or tight margins.

- Long charging times: Lead acid batteries can require up to 8 hours to reach full charge, as well as an additional 8 hours for the battery to completely cool before reuse. This means you’ll have to periodically swap out batteries as needed, a process that requires a special area and reduces the forklift’s productivity.

- Limited use cases: Electric forklifts not designed for outdoor use typically have low Ingress Protection (IP), which indicates their vulnerability to water and dust. The solid and cushion tires electric forklifts typically use can also experience instability on uneven, muddy or rough terrain common in outdoor environments.

Applications for Electric Forklifts

Applications where electric forklifts are more beneficial include:

- Warehousing and distribution: Because electric forklifts are compact and do not produce toxic emissions, they are suitable for navigating between aisles in warehouse spaces where ventilation is less than ideal.

- Retail: Electric forklifts are quiet, which makes them suitable for various retail operations such as transporting merchandise, stocking shelves and unloading deliveries without disrupting the customer experience.

- Cold storage: Specialized attachments enable electric forklifts to withstand low temperatures like those in refrigerated warehouses and freezer applications while maintaining high performance.

- Pharmaceuticals: Pharmaceutical manufacturing plants and health care facilities require clean air and quiet operation to maintain a sterile environment.

- Food and beverage processing: Due to their clean operation and the use of more hygienic smooth cushion tires, electric forklifts enable food and beverage plants to handle perishable products and packaging materials smoothly and efficiently.

- Material handling: Indoor facilities requiring efficient material handling can benefit from an electric forklift’s rapid torque generation and clean operation.

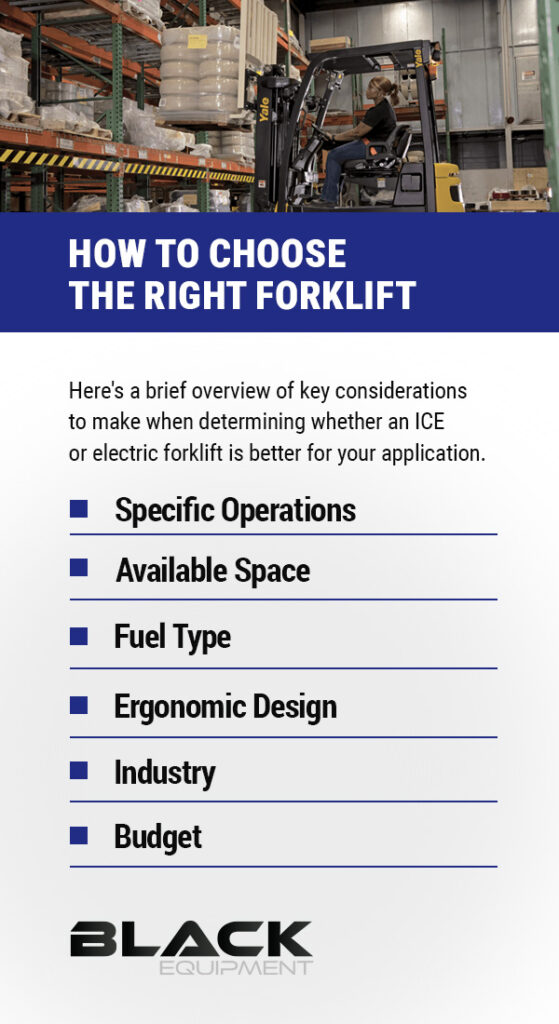

How to Choose the Right Forklift

It’s impossible to overstate the importance of working with a reliable salesperson when evaluating forklift options. While your team might have a strong understanding of which features you need and want, an experienced dealer can answer questions you may not have considered during your research.

Knowing which questions to ask an equipment provider upfront is a good place to start. Choosing between an ICE and an electric forklift begins by carefully defining the daily operational demands and workflows you require. Here’s a brief overview of key considerations to make when determining whether an ICE or electric forklift is better for your application.

1. Specific Operations

The tasks your employees complete on a daily basis are essential considerations for choosing a forklift.

For example, a construction site may require the high power and reliability of an internal combustion engine. The company’s risk of injury due to emissions is fairly low since they complete all their work in the open air, where fumes are likely not a problem.

Similarly, a food processing plant likely requires a quick, clean-operating electric forklift with a high-performance battery. Such a forklift keeps operations running while introducing less contamination and fewer safety risks.

Companies should also consider investing in specific forklift attachments to increase their equipment’s functionality. Depending on job requirements, a forklift attachment can significantly enhance efficiency and expand opportunities to generate revenue.

2. Available Space

Your forklift must fit into the jobsite’s overall layout to maximize your return on investment.

Electric forklifts are generally more compact than their ICE counterparts, which makes them easier to navigate through tight areas. They also provide precise control over maneuverability and acceleration, so they’re more suitable for indoor spaces as well as some outdoor jobsites where open space is limited.

ICE forklifts are typically larger and less precise. They rely on sustained power output and slower acceleration to complete demanding tasks. As a result, they’re better suited to more expansive outdoor jobsites where operators have wide space to maneuver.

3. Fuel Type

It’s essential to consider which fuel type is most appropriate for an ICE forklift. Each comes with its own benefits and drawbacks:

- Diesel: Diesel engines are the powerhouses of ICE forklifts in that they provide the highest torque, the longest run times and the easiest refill processes. The main drawback of diesel is its loud operation and high emissions production.

- Gas: Forklifts that burn gasoline and CNG are the least common due to the absence of available fueling stations in many areas.

- LPG: Also known as propane, LPG offers quieter ICE operation and high power. These engines work well for challenging outdoor tasks in remote areas where access to fuel is limited due to their long run time. Propane tanks are also easy to store.

Companies looking to entirely eliminate consumable fuel use should consult with a knowledgeable salesperson to determine whether an electric forklift will provide the power and continuity they need to meet their daily requirements.

4. Ergonomic Design

A forklift design that emphasizes operator safety and comfort is essential for several reasons:

- Raise employee morale: When operators feel safe and comfortable while on the job, they’re more likely to stay engaged with their work. This engagement is essential for maintaining a high employee retention rate and improving work quality.

- Maximize productivity: Ergonomics directly contributes to high engagement, and research has shown that employees who are engaged and comfortable at work are 18% more productive than those who are disengaged.

- Minimize risk: Ergonomic features like comfortably positioned controls and suspension seats with lumbar support can help reduce employees’ risk of developing musculoskeletal disorders (MSDs) and other work-related health conditions.

- Operator retention: A comfortable, safe and productive employee is a happy employee who’s more likely to stay — saving you the time and cost of finding and training a new operator.

When evaluating your options, be sure to ask a sales rep about what ergonomic design elements each model offers.

5. Industry

Regardless of the specific application, the industry you work in may have strict rules for which type of motive power you can use. For example, since pharmaceutical manufacturers must follow more stringent sanitation and noise requirements than manufacturers in other industries, they need forklifts that provide quiet, clean and emission-free operation.

The construction industry is an excellent example where one could benefit from both types of forklifts, depending on the application. An indoor renovation operation might need an electric forklift to reduce the risk of respiratory injuries and minimize noise pollution that might disturb other building occupants. An outdoor construction site, though, may require the high power and quick refueling that only an ICE forklift can provide.

6. Budget

Before you begin researching forklift models, it’s important to outline how much the company has to spend on new equipment. This information helps you determine which models are in your price range.

It’s equally important to consider how a forklift will fit into your typical operating budget. Because fuel prices change constantly, it can be difficult to predict ongoing expenses from quarter to quarter. An electric forklift may be more cost-effective for companies with low-intensity operations and more limited resources.

Financing plans and rental options are also ways to save money while using the equipment you need. The experts at Black Equipment can provide valuable insight into what arrangement works best for your company.

Find the Right Forklift for Your Application

If you want to upgrade your fleet, Black Equipment can help you find the equipment that optimizes your workflows, layout and application. We carry premium electric and ICE forklifts from brands known for their quality and reliability like Yale and Hyster.

Contact a Black Equipment salesperson online or visit your nearest location today to discuss your equipment needs.